Ceramic Metal Halide produces good quality lighting for plants. They seem to have a very large CRI, which suggests they imitate the efficiency of daylight. Most of the light emitted is in the PAR range. When CMH grows, lights emit a broad range of light, creating some Ultra Violet and InfraRed light. These array sections are very effective in preventing infections such as germs and bacteria and certain rodents.

Plants will grow healthier beneath CMH than LEDs grow lamps. Efficient energy LED growing lights to illuminate agriculture’s potential. They are economical in usage; they often yield healthier plants compared to other conventional lighting alternatives. Below, we will review how the LED lights evolve, how they influence plant growth, and what benefits the LED lights provide on the most commonly used artificial lighting in agricultural production.

CMH vs. LED Grow Lights: What’s the difference?

In the following post, you will find out whether CMH or LED grow lights are better for you in lighting,power consumption, budget and efficacy.

Adjusting Light Spectrum

CMH grows light devices are attached with a disposable bulb. It would help if you substituted the bulb with marginally redder (3100 K) or bluer bulbs of good quality (4000K). The frequency can be “adjusted” by several LED lights increasing. In principle, this involves turning red or blue diodes off while the light is rising. This limits the light intensity of the growing light grid considerably. CMH increasing lights in the CMH versus LED face-off provide a maximum intensity flexible range only by flipping the lamp. And the LEDs still can’t.

The Growing Intensity of Light

Increasing luminous sources is an exciting and confounding aspect to remember. I’m going to go a little into the depth, but the main argument is that CMH grows light provides far more intensive light than LEDs ever will. The density corresponds directly to the thickness of the canopy. Here is the theory, the “inverse square norm” is the physical law of illumination. It says that the light strength is inversely proportional to the distance from the beam of light. Of course, led lights and light sources adjust somewhat, but the reality that the lightweight strength decreases slowly does not change.

A Light Refresher

Plants usually consume a particular part of the photosynthesizing active radiation or limited PAR in a visible spectrum. The quantity is generally identified as PARWatts, which correspond directly to the sum of power that reaches the meter per period in the PAR segment of the wavelength of light. Please you should never use standard light bulbs for growing plants because it’s not worth the cost comparing to the results.

We have used CRI to explain how close the light source produced by our growing light is sunlight. Others like PPF, PPFD, and others are visible, but they relate to overall lighting and light strength but not directly to spectrum. Most farmers also know how to use blue lights, such as metal oxides, in photosynthetic and reding phases, such as high-pressure mercury lights, in growing steps.

The Effect of Lighting Temperatures on Growing Room Temperatures

LEDs are electrical instruments, and the diode inside an LED does not provide the majority of the energy produced. All of the internal components supply the bulk of the power: ballasts, motherboards, cooling fans, etc. The wires and chips that make up diodes may get hot. As a result, the lights would turn warm after a while of working at high wattages. However, also the most potent LEDs do not get as hot as HIDs. HID growing lamps, unlike LEDs, are powered by gases rather than wires or chips. Mercury and metal halides, among other gases and chemicals used in HID development lamps, react to illumination.

As the bulb grows lighter and lighter, heat is emitted. That’s a lot of sunlight, and the lamp can absorb it. The heavier the bulb and the evolving room become as the frequency and duration are increased. It’s important to note that CMH’s function the same way that normal MHs do, only that they have concrete bases.

On the other hand, Ceramic halogen lamps run at a temperature of around 8 degrees Fahrenheit cooler than MH and HPS lights. A smaller LED ran at least 2°F cooler than a CMH, and a larger LED ran at least 10°F cooler. (*Keep in mind that LEDs come in a variety of wattages and shapes.) Different lamps produce different amounts of heat.)

CMH vs. LED: Which Grow Light is the Most Effective?

Light Emitting Diodes (LED) and Ceramic Metal Halide (CMH) only specific devices have progressed from strong magnetic, ineffective reflectors and cumbersome reflectors to hyper electronic ballasts and range switchable LED CMH only those displays. The new hobbyist and industrial cultivator can now dial in spectrums unique to the plant species being grown. With a switch of a knob, LEDs can go from a usable photosynthetic light to a red floral range.

CMH’s strongly resemble the sun, provide the maximum degree per watt, and emit the coveted good UV wavelengths, which help prevent mold and mildew while also stimulating plant vigor and resin and terpene processing. The size of it expands, along with the length of time you’ll be increasing in the room, and you’re spending all time deciding which light is best for you.

Let’s talk about the size of your crop. Due to the loss of total canopy absorption, you should place your LED lights 12-18″ below your canopy. This could be a good idea if the ceiling height is less than 8 feet, and you need to consider heat management. If you have a more excellent and more open room, CMH creativity is a better option. Enhanced ceiling height improves heat management, drainage capability, and even lighting visibility for broader and larger flower plants. LED lights produce very little heat, which can be beneficial or detrimental depending on your grow room’s size and your plants’ temperature.

If you work in a colder environment, proper space insulation is essential throughout the winter months. Since LEDs produce less heat, more heat could be needed in the grow room during the colder months, raising costs. CMH bulbs generate more heat than LED bulbs but less heat than HPS bulbs. For example, if you’re using CO2 injection, this heat could be used to get the growing process to the right temperature.

Finally, there’s the BUDGET, which is everyone’s favorite thing to keep in mind. At first, an LED fixture costs 2 to 4 times as much as a comparable CMH fixture. LED fixtures, especially those that use the UV spectrum, are costly upfront. LEDs save the grower some 15% on their energy bill than CMH fixtures in power use and statement.

On the other side, the LED grower will use less power for cooling, but the sum saved would be determined by other variables in the grow space. Bulb repair will be an additional cost for a CMH grower. You’ll need to replace your CMH bulbs after 12-18 months of operation.

Furthermore, during the vegetative to flowering process, you can switch from 4100K CMH bulbs to 3100K CMH bulbs. You can incur higher lamp costs as a result of adopting CMH technology. However, you can maximize the number of light cycles and the time between bulb replacements.

To summarize, all CMH and LED technologies have the potential for sustainable development, but their methodologies and commercial initiatives vary.

When to Choose CMH grow lights?

- Within 1-2 years, you would increase your return on investment.

- For the strains you’re developing, you’ll need further canopy penetration.

- For total terpene resin output, the UV spectrum is needed.

- You want to get the most bang for your buck in terms of gram per watt and flower efficiency.

- You could be eligible for state rebates if you meet those criteria.

When to Choose LED grow lights?

If you want to save money, go for LED.

Make a long-term strategy for today’s LED technologies.

To develop a particular strain, you’ll need an exact spectrum wavelength.

You could be eligible for state rebates if you meet those criteria.

The quantity and consistency of the yield are not the most critical factors.

Benefits & drawbacks of CMH grow lights

The Benefits

- CMH’s last times as large as MH or HPS bulbs on average.

- CMH’s perform even hotter than MHs due to the ceramic aspect, providing a light similar to solid daylight. However, they have reduced power consumption because of their porous value, which implies they are less likely to destroy plant leaves than MH or HPS bulbs.

- CMH’s may provide a light range suitable for both the seedlings and flowering stages of plant development.

The Drawbacks

- Only metallic metal halides could be used for CMH lamps, and they must be mounted perfectly straight or horizontally.

- The price. They are all somewhat expensive since they are a newer technology.

- The amount of UV light emitted by CMHs poses a threat to growers. If producers are going to be operating under CMH illumination, they can wear baggy shirts and shades.

Benefits and drawbacks of LED grow lights

The Benefits

- LEDs are power rich and are one of the cheaper incandescent lamps for use. They make less illumination per watt than fluorescent lights or HIDs. There are, however, variations to this.

- LEDs are running at colder temperatures. In addition to energy efficiency, it ensures that the risk of consuming your plants is significantly less than for any other crop lamps. They are also among the longest-term choices for artificial illumination.

- They may generally be directly connected to conventional outlets; certain varieties may also be found in typical light fixtures (no ballasts required for LEDs).

- The color spectrum is broad and can be customized and adjusted based on the crop and growth stage.

- Many manufacturers produce LEDs with a variety of features and advantages.

- LEDs are commonly deemed the simplest to use

The Drawbacks

- The cost of opting for LEDs could be prohibitory. They are also more costly than other alternatives for growing the sun.

- Some LEDs produce less light than other varieties of increasing lights in an attempt to lower consumer costs. This can be avoided if the chosen LED light is 2.0 micromoles per watt of electricity.

- LEDs are not necessarily good enough for the flowering period relying on the producer. This disadvantage can become redundant when technology advances, and some LED systems also now provide enough light, so make sure that you pick the best LED for your specific crop.

- Mirrors could be essential to make full use of your LED lights. That might not be a genuine “con,” though, unlike HIDs, where most LED structures are intended, they are marketed so that no other products are desired.

What We Recommend?

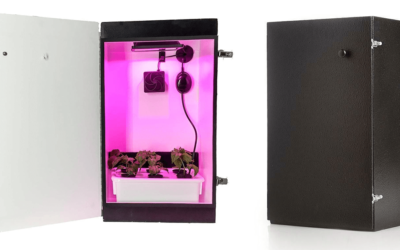

We have extensively compared the CMH and LED grow lights. As I have reached, both LEDs and CMH grow lights are successful in plant growth. CMH produces lights for business and hobbyists with enough room. They grow larger and denser buds and provide a wide range of alternatives. On the other side, LEDs are ideal for hobbyists with narrower areas such as tents. And it’s perfect for people who thrive in lower ceilings areas. LEDs are also perfect for canopy decoration.

In contrast, CMH-led bulbs are far more reasonable. LED’s save producer just about 15 percent on the electricity bill when it comes to economic use and power cost relative to CMH. Therefore, the LED grower uses less power for freezing, but savings rely on other area growth variables.

That’s where LEDs have an advantage over the CMH lights. They do not even put as much warmth as the CMH does. This ensures you would be cooling a space packed and LEDs with fewer air conditioners than the place filled with ceramic radiation detectors. There is a significant sum of electricity saved. About half the time are the torches. The growing lights and the air conditioning units that cool the space are far less running.